INTRODUCING THE SPANTECH W SERIES

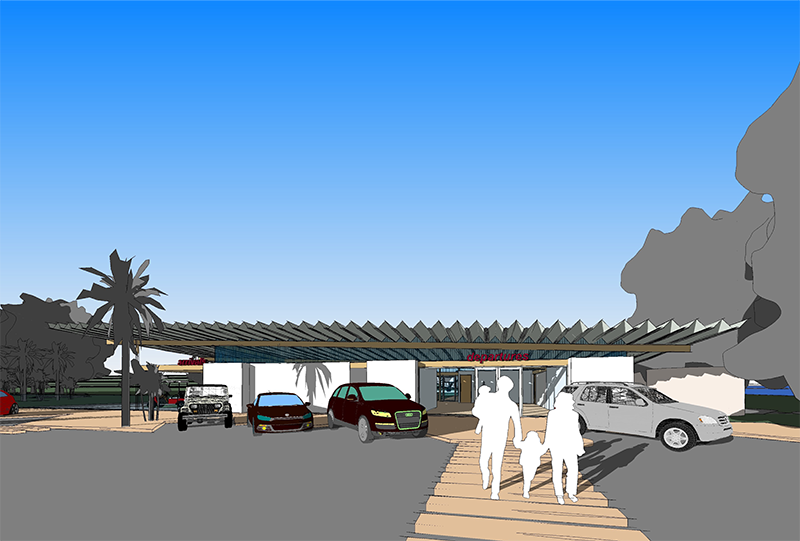

STEA Architects designed, documented and administered the construction of the new Lord Howe Island Airport Terminal.

The terminal caters for two simultaneous Dash 8 aircraft with a seating capacity of 30 passengers each. While only a relatively small building, the terminal provides an appropriate and unique gateway to this spectacular world heritage destination. So STEA were seeking a bold statement for the roof.

The roof had to be a wide-span aluminium roofing system to withstand the highly corrosive island environment. The supplier also had to meet the logistic challenges for the remote project. Panel length and weight limitations applied to all materials being shipped from the mainland. The design and installation had to account for the limited construction resources on the island.

STEA and Spantech had successfully collaborated on a number of challenging aviation projects in the past. So while they considered other roofing profiles such as Aramax, STEA were confident Spantech could deliver.

The Spantech W Series in Aluminium was nominated for the project. The ceiling is also made with the Spantech W Series in perforated aluminium. Both were provided in the 650mm cover width and manipulated on site to the required cover.

The W Series proved more affordable than alternatives. The span characteristics were superior, particularly in aluminium, with 2.5m cantilever eaves achieved. Spantech also assisted with the design and delivery of bespoke fittings and connections. Spantech’s unique ability to meet the construction deadline was a paramount consideration for STEA.

SITE LIMITATIONS

As the maximum panel length was just over 9m, Spantech devised a method to join the Spantech W Series panels. Spantech created a personalised video to help train the roofing plumbers and ensure the Spantech W Series panels were installed correctly and remained strong and waterproof.

LIGHT WEIGHT CONSTRUCTION

The frame of the building is timber, much of it recycled. Spantech’s Engineer devised a method to fix the Spantech W Series panels securely to the timber beams with a series of pre-cut timber blocks and coach bolts. The solution is simple to build, cost effective and makes the Lord Howe Island Airport Terminal aesthetically pleasing.

MATERIAL SPECIFICATION

Roof

Spantech W Series, 600mm, 620mm and 745mm cover width, roll-formed embossed aluminium roof sheeting with film, 1.6mm (BMT) thick 5251 H34 grade.

Ceiling

Spantech W Series, 600mm, 620mm and 745mm cover width, roll-formed perforated and embossed aluminium ceiling sheeting without film, 1.2mm (BMT) thick 5251 H34 grade.

MORE INFORMATION

- Spantech Technology for more about the W Series and other Spantech profiles

- STEA Architect’s website: www.stea.com.au

- Lord Howe Island Board: www.lhib.nsw.gov.au